Technical Parameters

Place of Origin:

Dongguan, China (Mainland)

OEM:

Yes

Process:

Soldering

Temper:

T3-T8

Material:

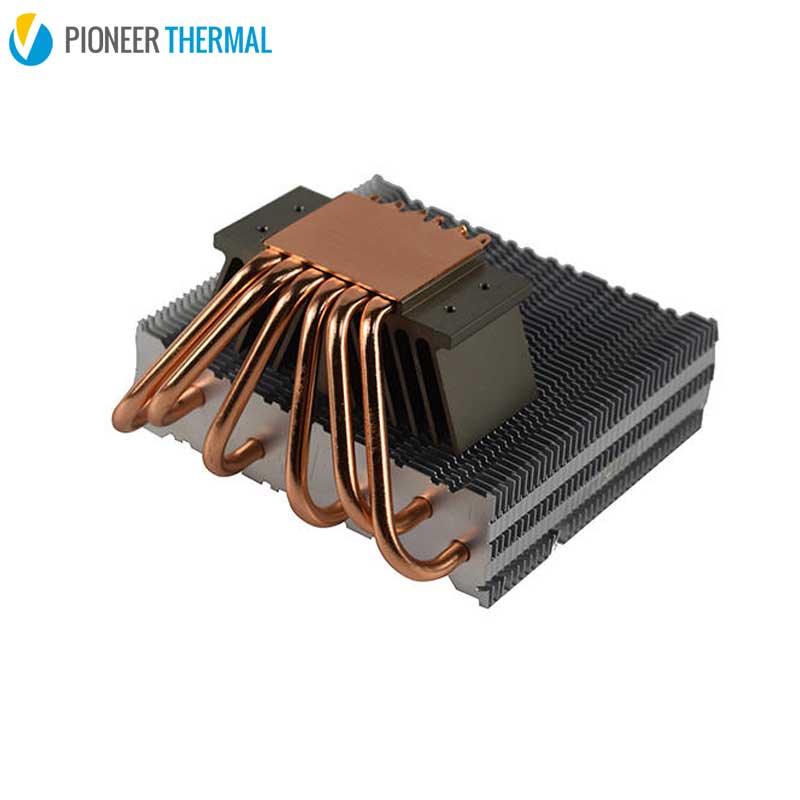

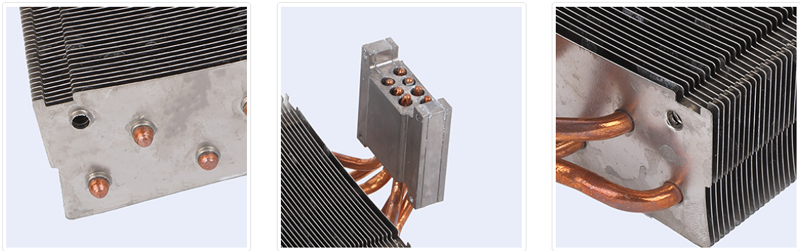

Aluminum heat sink + heat pipe

Shape:

Customize

Packing:

Paper carton with wooden pallet

Brand Name:

PIONEER THERMAL

Application:

Telecommunication, server, solar energy, PV inverter, power supply

Certificate:

ISO 9001:2015,ISO 14001:2015, TS16949

Model Number:

PT034

Tolerance:

0.01 mm

Finish:

Chemical nickel plating

Quality control:

100% on-line thermal test

Extra process:

Stamping+CNC Machining

Size:

Custom size

Applied Field:

Telecommunication, server, solar energy, PV inverter, power supply

Heat pipe heat sink has the following advantages:

1. Fast thermal response speed, Its heat transfer capacity is more than 1,000 times greater than that of copper tubes of the same size and weight;

2. Small size and light weight;

3. High heat dissipation efficiency, can simplify the heat dissipation design of electronic equipment, such as variable air cooling for self-cooling;

4. Do not need external power supply, work without special maintenance;

5. Has a good isothermal, thermal balance, the evaporation section and cooling section of the temperature gradient is quite small, can be approximately regarded as 0;

6. Safe and reliable operation, does not pollute the environment.

As a heat sink manufacturer in China, Pioneer Thermal is certified

with ISO9001, ISO14001 and TS16949, and has more than 18 years experience

in CNC machining, cold forging heatsinks, cold plate heatsinks, die

casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin

heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal

has own R&D team who can design and run simulation for you if you

require design service, or assist your design team to improve the part

feasibility from the manufacture point of view (design refine/process

optimize/cost reasonable). If you need any heat sink service, please contact

Pioneer Thermal.

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語