Skiving Heatsink Introduction

Skiving heatsink advantages

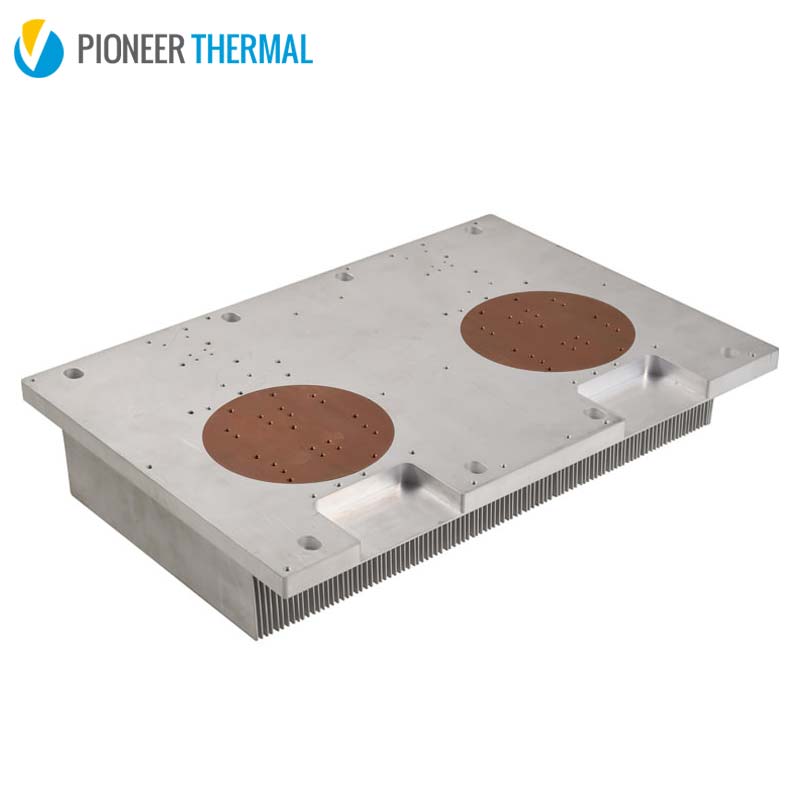

This skiving heatsink is very long with 1200 mm, and have fins in two sides: one side fin is skived fin,and the other side fin is extrusion fins. This skiving heatsink combined the advantage of extrusion and skived technology.

Process of this skiving heat sink:

1. Make extrusion mold for the base and extrusion fin heat sink.

2. When the heat sink material get from extrusion, put the skiving heat sink material on the skived machine, cutting the base and form the skived fin.

3. Machine the hole on the heat sink for assemble and finished with silver anodized.

This skiving heat sink can be an alternative to extruded heat sink when looking for high density which can’t be achieved by extrusion technology.

Skiving Heatsink Aluminum Technical Parameters

AL1060 / AL 6063/ CU1100 Process parameter:

Place of Origin:

Dongguan, China (Mainland)

OEM:

Yes

Process:

Skiving fin

Temper:

T3-T8

Material:

AL6063

Shape:

Customized

Packing:

Paper carton with plywood pallet

Brand Name:

PIONEER THERMAL (PT)

Application:

high power devices

Certificate:

ISO 9001:2008,ISO 14001:2015, TS16949

Model Number:

PT043

Tolerance:

0.05 mm

Finish:

Silver Andoized

Fin thickness:

0.25 --2 mm

Extra process:

CNC Machining and extrusion

Size:

1200*200*150 mm

Applied Field:

Telecommunication, UPS, inverters, controllers, wind power converters, and SVG

Base thickness: 1~30 mm Fin length: <550 mm Fin height: <120 mm

Fin thickness: 0.25~2.0 mm Fin gap: 0.2~6.5 mm Product length: 3000 mm

Our Customers

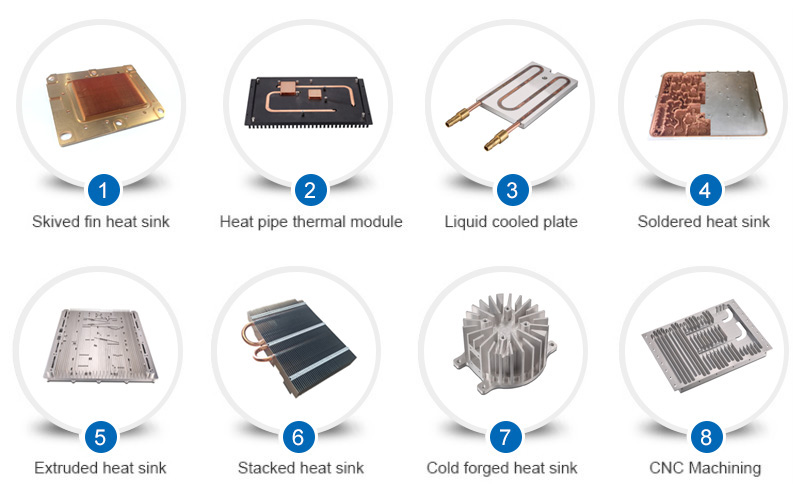

Most of PT heatsink product are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

PT heatsink can assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable)

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語