Product Introduction

Skived fin heatsink process video:

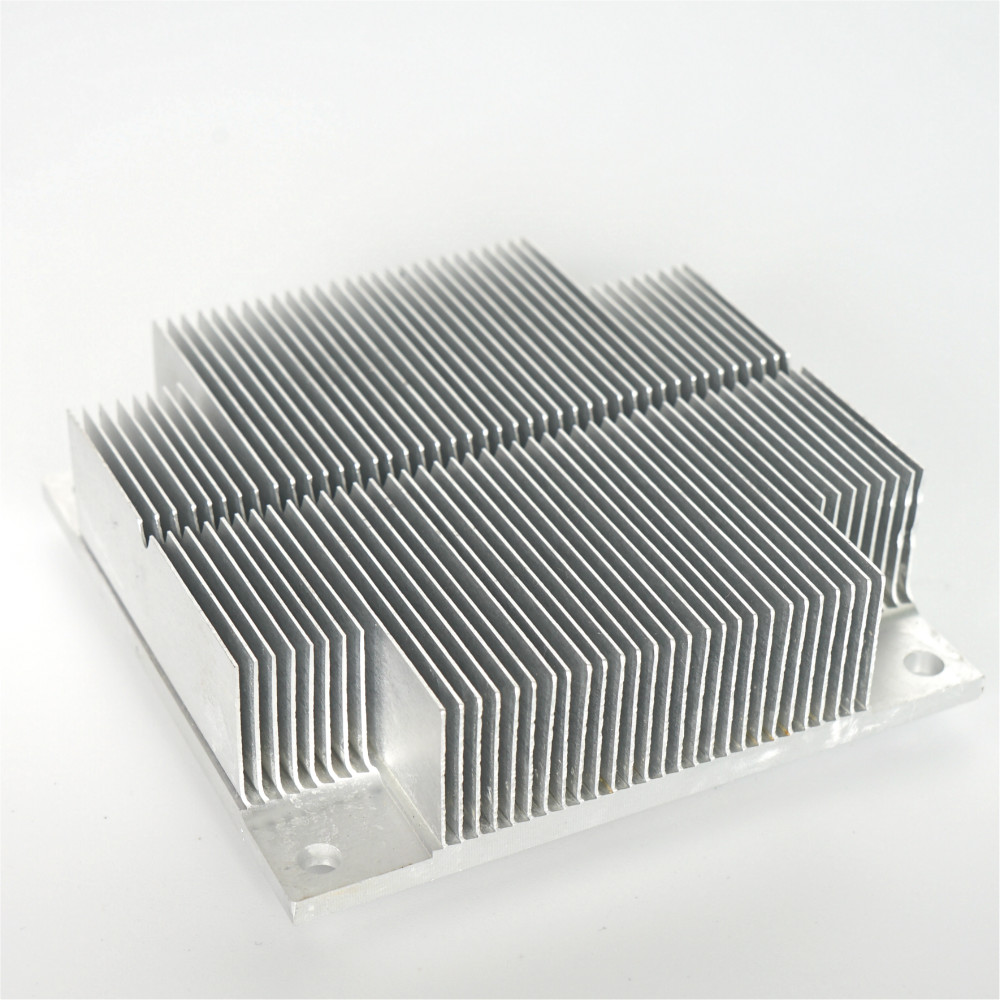

Skived fins are

achieved by a knife tool that literally shaves fins up from an

extruded aluminum or copper base. This process of slicing and

then standing the fins up one at a time can create an extremely high

fin-to-gap aspect ratio. The top of the fins are then cut to maintain a uniform

height. This increased surface area drastically improves the thermal

performance in forced airflow environments.

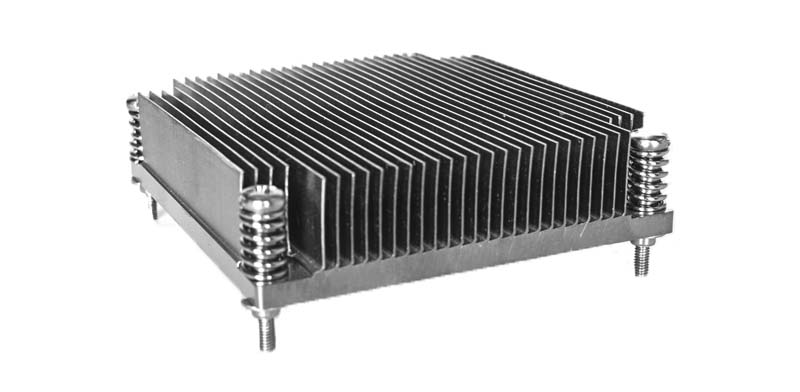

Advantage of Skived Fin Heat Sinks

· High aspect ratio

· Thin fin

· Low tooling cost

· Easy and inexpensive to prototype

· Ideal thermal connectivity with the heat sink base

· Unidirectional flow

· Single piece construction

Skived fin

heat sinks are commonly found in the following applications:

Computers and

electronic components

Telecommunication

equipment

Industrial

equipment and components

Lighting lamps

and household appliances industry

Automotive

components

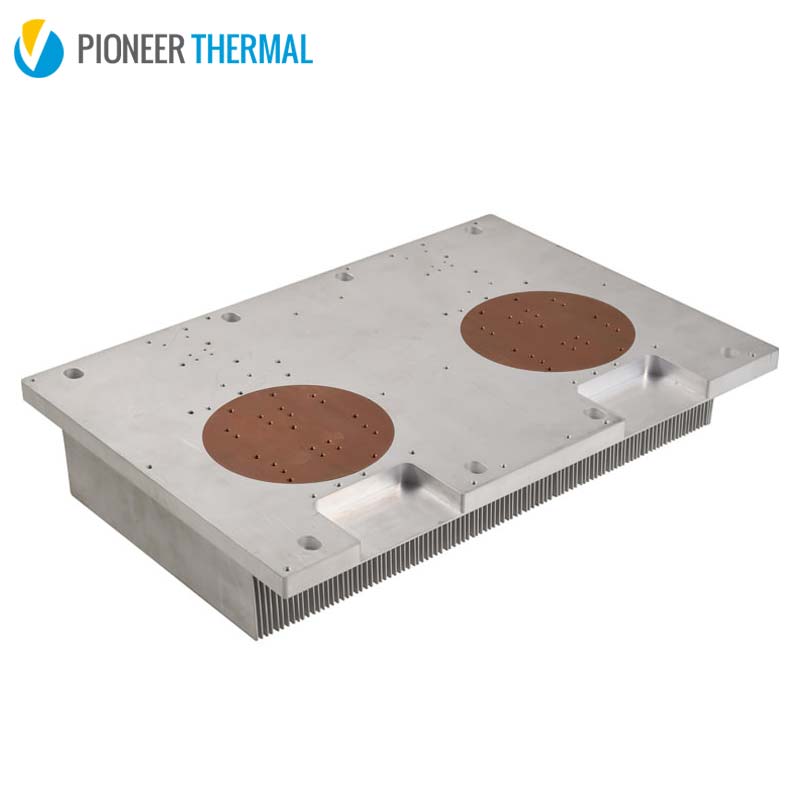

As a heat sink manufacturer, Pioneer Thermal has more than 18 years experience in CNC machining, cold forging heatsinks, cold plate heatsinks, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heatsinks etc., Pioneer Thermal has own R&D team who can design and run simulation for you if you require design service, or assist your design team to improve the part feasibility from the manufacture point of view (design refine/process optimize/cost reasonable). If you need any heat sink service, please contact Pioneer Thermal.

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語