Product Introduction

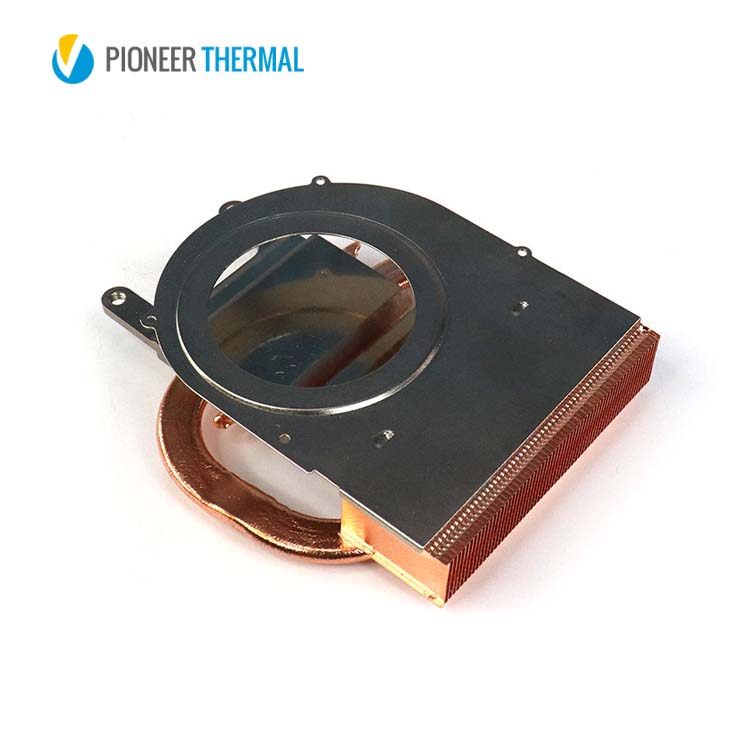

Copper heat sinks are a popular thermal management choice among computer customisers because of their ability to absorb heat relatively quickly.

A major advantage of copper heatsinks is their thermal conductivity. Compared to other materials, copper conducts heat away from its source more quickly. It functions well as a heat sink because copper can effectively transfer heat from the source to cooler materials - usually air

Pioneer Thermal's copper heat sink can be standard or customized, we can also design the copper heat sink based on customer's thermal input, after customer's approval on the design, we can then build prototype to verify the thermal performance.

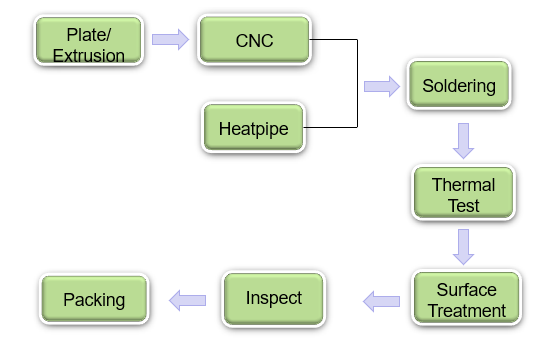

Copper Heat Sink With Heat Pipe Process:

Available heat sink process of Pioneer Thermal:

| Main Process | Extrusion | Bonded Fins | Skived Fins | Snapped Fins | Folded Fins | Heat Pipes |

| Cold Forging | Die Casting | FSW cold plate | Gun drill cold plate | Vacuum brazing cold plate | Vapor chamber | |

| Finishing Processes | CNC machining | Drilling | Tapping | Stamping | Anodizing | Screen printing |

| Powder coating | Laser etching | Polishing | Electrophoresis | E-coating | ||

| Finishing Value Added | Embedded fans | Thermal Greases | Screws | Springs | Clips | Embedded heat pipes |

| Phase change materials | Back plates | Gap filler pads | PEMs | Standoffs | Dielectric pads | |

| Compounds | ||||||

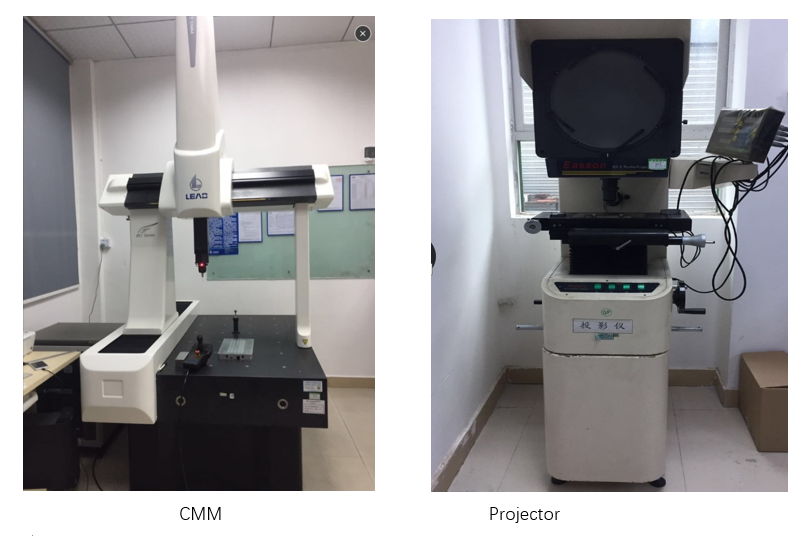

Pioneer Thermal Quality Assurance:

Inspection tool of Pioneer Thermal:

| Heat sink dimension | |||||

| CMM | Projector | ||||

| Heat sink performance | |||||

| Salt Spray Tester | Pressure Tester | Clip Force Tester | Drop Tester | Helium Leakage Tester | |

| Heat sink reliability | |||||

| Wind Tunnel | On Line Thermal Tester | HP Qmax Tester | HP Delta T Tester | Thermal Shock | High Temperature Aging Chamber |

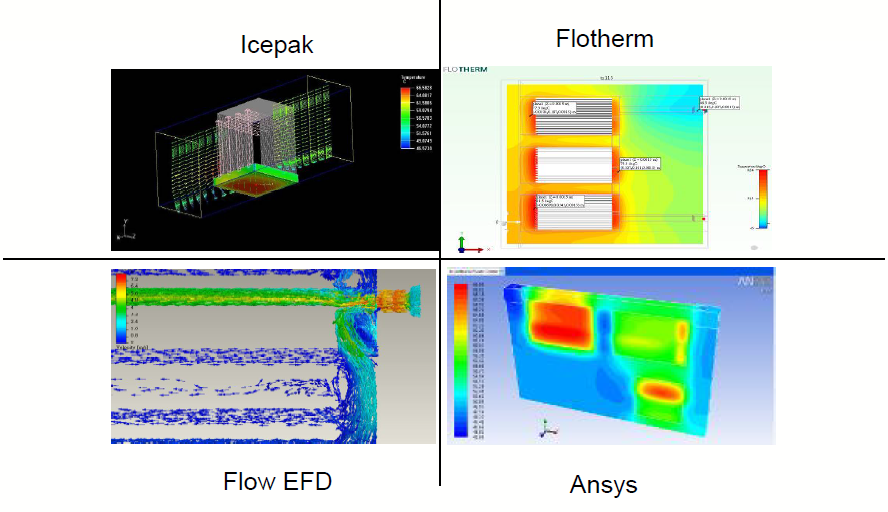

Pioneer Thermal R&D:

About Pioneer Thermal:

As a heat sink manufacturer in China, Pioneer Thermal is certified with ISO9001, ISO14001 and TS16949, and has a dedicated quality assurance department with full CMM capabilities. We are focused on providing advanced technology, superior customer service and outstanding value to our industry partners.

English

English Español

Español Deutsch

Deutsch Français

Français 日本語

日本語